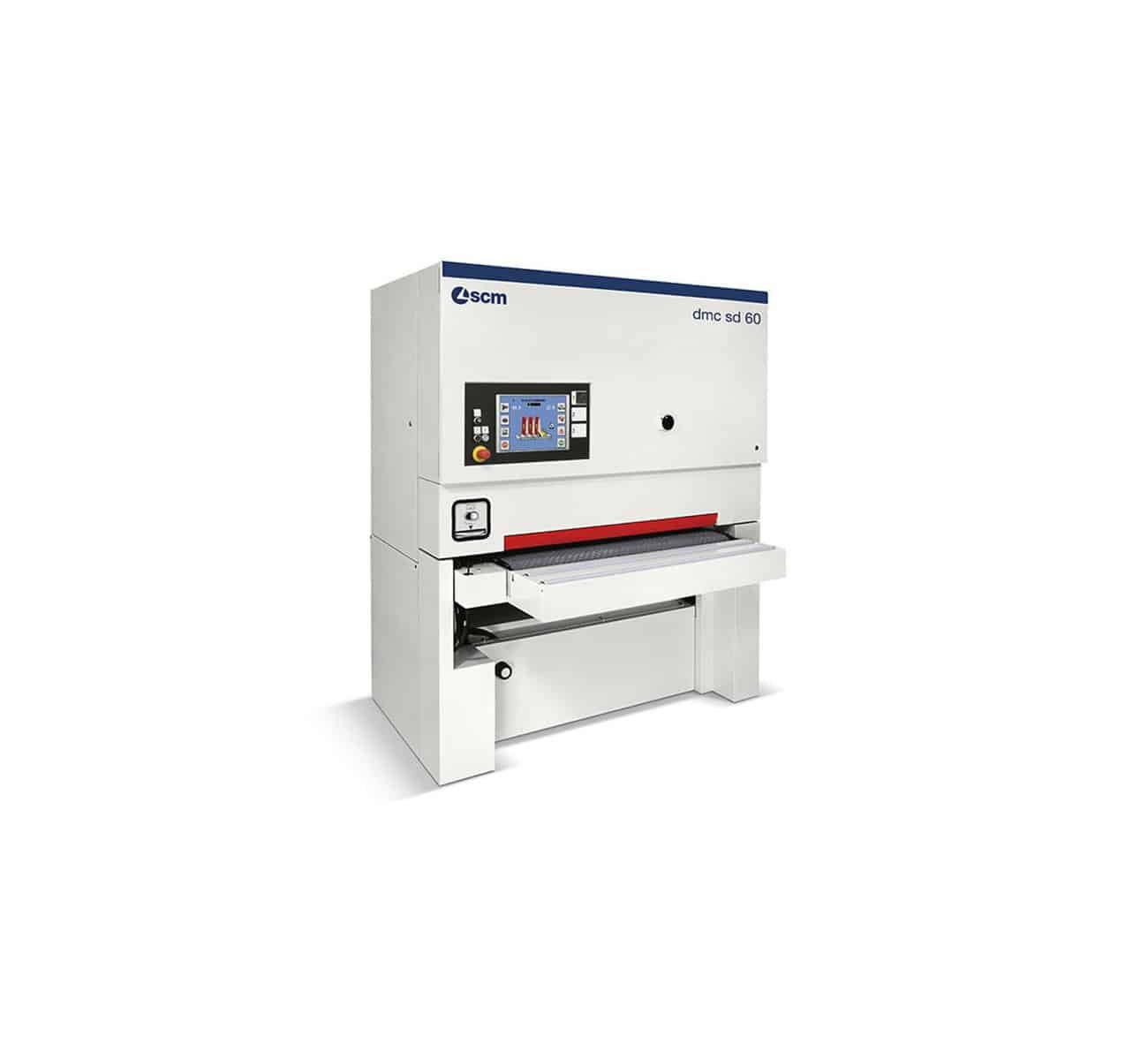

About this Machine:

- 2-head 53″ wide capacity

- 1st head: 140 mm (5.5″) dia. steel calibrating drum with 30 HP motor

- 2nd head: Combination 160 mm (6.25″) 45 durometer rubber drum with 60 mm (2.36″) wide

- “TES” air cushion pad platen with 2 removable inserts

- 170 mm (6.69″) max. Part thickness

- Uses 53″ x 85″ abrasive belts

- Automatic feed belt tracking

- 12 to 60 FPM feed speed with a 2 HP feed motor

- 50 Durometer seamless waffle style feed mat

- Adjustable automatic electronic thickness setup device

- Powered table lifting by means of four heavy duty motor and lifting columns double fastened at both top and bottom of the lifting

- columns to provide exceptional table stability

- Electronic digital table height indicator

- Logic 50 K electronic controller for timing/anti-dubbing of the pad

- 2 roller infeed and outfeed roller table extensions for easier part feeding

- Includes Y-Delta 2-stage reduced voltage starter on main motor with amp meter, main disconnect switch with the ability to be

- locked, front and rear emergency stop buttons

- Electrical Requirements: 150 amps @ 230 volts 3-Phase

- Dust Extraction: 3,544 CFM with (2) 195 mm (7.75″) dust outlets

- Air Requirements: 6 Bar (88 PSI)